The Unstoppable Rise of Robots in Manufacturing | Robots4Good

The Unstoppable Rise of Robots in Manufacturing | Robots4Good

Revolutionising the Factory Floor: The Unstoppable Rise of Robots in Manufacturing

Embracing the Future, Today

In an era dominated by rapid technological advancements, the integration of robots in manufacturing stands out as a transformative force, reshaping the very fabric of industrial production. As we dive into this technological renaissance, we invite you on a journey to explore how these mechanical marvels are not just altering, but revolutionising the way we manufacture, create, and innovate. This is not just a story of machines and automation; it is a narrative of efficiency, precision, and the relentless pursuit of excellence.

Unlocking a World of Possibilities

In this comprehensive exploration, we will unravel how robots in manufacturing are not just tools of automation, but catalysts of change, driving efficiency, precision, and innovation. From small-scale enterprises to global conglomerates, the adoption of robots in manufacturing is a testament to their unparalleled benefits. By the end of this article, you will be equipped with a thorough understanding of the transformative impact of robots in manufacturing, and how telepresence robots, in particular, are paving the way for a future of seamless integration and unparalleled efficiency.

The Dawn of a New Era: Robots in Manufacturing

Unleashing Productivity

Robots in manufacturing have become synonymous with precision and efficiency. Their ability to perform repetitive tasks with unwavering accuracy has not only streamlined production processes but also significantly reduced the margin of error. In industries where precision is paramount, robots in manufacturing have been a game-changer.

The Ripple Effect on Workforce Dynamics

But what does this mean for the workforce? Are jobs being displaced, or are new opportunities being created? The narrative is complex, and the answers are not black and white. As we navigate this new era, it is crucial to understand the multifaceted impact of using robots in manufacturing and the opportunities and challenges.

The Human-Robot Collaboration: A Partnership for the Future

Cobots: Enhancing Human Potential

The advent of collaborative robots, or cobots, has fostered a harmonious relationship between humans and machines. These robots are designed to work alongside humans, enhancing productivity and ensuring a safer working environment. The integration of cobots in manufacturing processes is a testament to the synergistic potential of human-robot collaboration.

Assisting Not Replacing

Cobots are not meant to replace human workers; instead, they serve as tools that amplify human capabilities. They take on repetitive, strenuous, or precision-demanding tasks, freeing up human employees to focus on more complex, creative, or decision-making aspects of the work. This division of labour not only leads to increased productivity but also enhances job satisfaction for human workers, as they are able to engage in more meaningful and rewarding aspects of their work.

The Future of Human-Machine Collaboration

As technology continues to advance, the potential applications for robots in manufacturing are vast and varied. From assembly and packaging to quality inspection and material handling, cobots are proving to be valuable assets in a wide range of settings. They represent a significant step forward in the evolution of human-machine collaboration, highlighting a future where humans and robots work together seamlessly to achieve common goals.

Striking the Right Balance

But how do we ensure that this partnership thrives? How do we strike the right balance between automation and human intuition? These are critical questions that need to be addressed as we continue to integrate robots in manufacturing. Let’s turn to telepresence robots, which have a special role in the line-up.

Telepresence Robots: A Game-Changer in Manufacturing

Bridging the Gap: The Power of Presence

The Virtual On-Site Expert

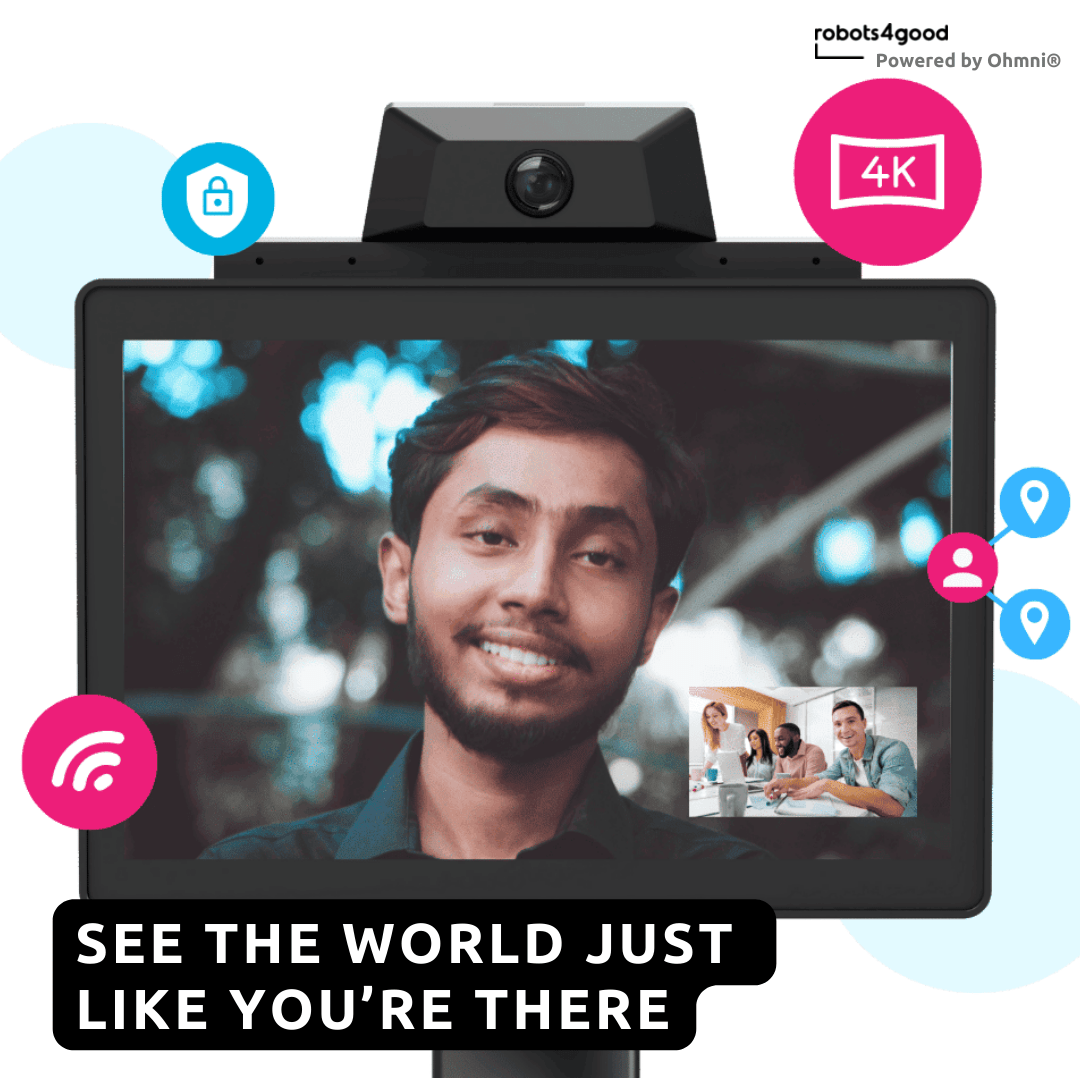

Telepresence robots are redefining the boundaries of communication and collaboration in the manufacturing industry. By providing a physical presence remotely, these robots enable experts to be virtually on-site, ensuring that critical decisions are made swiftly and accurately. In a world where time is of the essence, telepresence robots are a game-changer.

Doing Gemba Walks

Telepresence robots revolutionise Gemba walks in manufacturing, allowing customers to conduct product inspections remotely yet thoroughly. These robots provide real-time, immersive experiences, ensuring that customers can closely examine products and processes without being physically present, thereby saving time, reducing travel costs, and maintaining high standards of quality assurance.

Immediate Assistance, Anytime, Anywhere

The deployment of telepresence robots in manufacturing not only enhances accessibility but also significantly reduces downtime. Their ability to provide immediate, on-site assistance, regardless of geographical constraints, ensures that operations run smoothly and efficiently. In an industry where downtime can have significant financial implications, telepresence robots are a valuable asset.

The Future is Now: Embracing Robots in Manufacturing

Laying the Groundwork for Automation

The integration of telepresence robots in manufacturing requires careful planning and strategic implementation. From selecting the right robots to ensuring seamless integration, every step is crucial. As we navigate this transition, it is essential to consider the long-term implications and ensure that we are laying the foundation for a future-proof manufacturing environment.

Addressing Challenges and Embracing Change

Key considerations for a smooth transition to robots in manufacturing include thorough planning, employee training, and bespoke technical integrations. Of course, ensuring clear communication, involving staff in the process, and providing on-call technical helpdesk are key. Designing, testing, and improving human-robot workflows will reduce resistance, and build the bridge to maintaining a flexible approach to evolving opportunities and challenges.

The ROI of Robots in Manufacturing: A Worthwhile Investment

Calculating the Long-Term Benefits

The initial investment in telepresence robots in manufacturing can be modest, but the long-term benefits far outweigh the costs. From increased productivity and efficiency to reduced labour costs and error rates – and better safety - makes the return on investment potentially substantial. In a competitive industry, the adoption of telepresence robots in manufacturing settings is not just a strategic move; it could be a necessary one.

Measuring Success and Ensuring Sustainability

Start working on your business case. Quantify the benefits by analysing productivity gains, cost savings, and improved safety. Measure success through enhanced collaboration, reduced travel, and increased operational efficiency. Start by deploying a single robot and measure the benefits it creates and value it generates. You can start small and scale if the cost-benefit stacks up.

The Future is Bright with Telepresence Robots in Manufacturing

As we look to a rapidly advancing technological era, the integration of robots in manufacturing is not just inevitable, but essential. The precision, efficiency, customer support and opportunities that they bring to the table are unparalleled, and their transformative impact is evident. By embracing telepresence robots, we open the doors to a world of possibilities, ensuring that no matter where we are, we are always present, always connected. So much more is within our grasp.

Transform Your World with Telepresence

Are you ready to take the leap into the future? Book a discovery call today, and let us show you how telepresence robots can transform your manufacturing processes, enhance your efficiency, and connect you to a world of endless possibilities. Don't just be a part of the change; be a leader in the revolution. Transform your world with telepresence today.

About Robots4Good

As a leading provider of robots as a service, Robots4Good is the exclusive supplier of OhmniLabs services and robots in Australia and New Zealand for business, manufacturing, schools, hospitals, disability and aged care settings.